Düz ve gofrajlı polietilen film, İlka Hood, shrink film, eva torba gibi çözümlerle endüstriyel alanda koruma sağlayan İlka Ind, esnek çözümleri ile işinizi güvenle yürütmenize katkı sağlar.

İlka Plast stretch film, buzdolabı poşeti, çöp poşeti, market poşet ve rulo poşet gibi ürünlerden oluşan geniş bir ürün gamına sahiptir. Gıdalarınızın raf ömrünü uzatan stretch filmler; gıdalarınızı güvenle muhafaza etmenizi sağlayan buzdolabı poşetleri; delinme ve yırtılmaya karşı dayanıklı rulo poşet ve market poşetleri; dayanıklı, sızdırmaz ve koku geçirmez çöp poşetleri ile hem endüstriyel alanda hem mutfak grubunda esnek çözümler sağlar.

İlka Pack, gıda muhafaza pazarına hitap eden, çok katlı farklı yapıdaki filmleri üretmek üzere makine ve alt yapı yatırımları gerçekleştirmiştir. 9 katlı Bariyer Pe Balon hattı ve 5 katlı OPE Balon Hattı yatırımları yapılarak, OPE Film, Laminasyon Filmi, Bariyer Film, Compressing Film, Koruma Filmi ve Shrink Film üretimi gerçekleştirilebilmektedir.

Kanık Şirketler Grubu bünyesinde plastik ambalaj sektöründe faaliyet gösteren İLKA Plastik, 1983 yılında Kocaeli’de kuruldu. 20.000 metrekarelik üretim ve depolama tesislerinde plastik ambalaj sektöründe endüstriyel alanda ihtiyaç duyulan ürünleri üretip müşterilerine ulaştırmaya devam eden İLKA, son teknoloji kullanarak ürettiği ürünlerini sektör ihtiyaçlarına göre her geçen gün geliştirmekte ve müşterilerine en iyi hizmet verme politikasıyla süreçlerini yönetmektedir.

Daha Fazla

Sektörün önde gelen markalarından İlka Plastik, bu yıl satış tonajını yüzde 27, cirosunu ise yüzde 250 oranında artırdı. Alt yapı ve teknik donanım yatırımlarını tamamlayan İlka Plastik, faaliyete geçireceği Ar-Ge merkeziyle ürün ve hizmetlerinde daha da öne çıkacak. Hızlı büyüyen şirket, 2022 sonunda 7 milyon dolar ihracat hedefliyor. daha fazla

İlka Plastik Ar-Ge Merkezi oluşum süreci incelendi. Yeni yatırımlar ile beraber Ar-Ge kapsamında yapılmış olan yeni projeler heyet ile birlikte değerlendirildi. İlka Plastik’in mevcutta sunmuş olduğu ürünler ziyaretçilere anlatılırken Ar-Ge ile beraber planlanan projelerden de bahsedildi. daha fazla

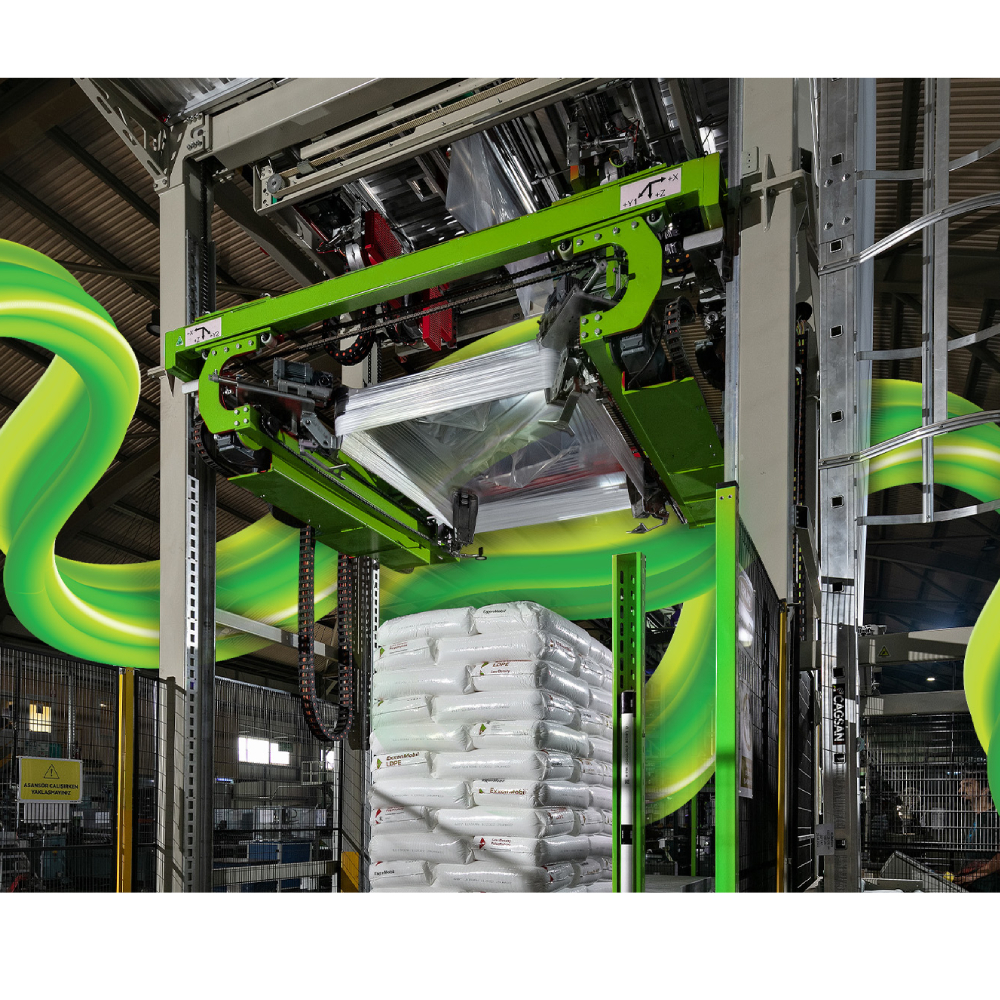

İlka Plastik, palet üzerinde paketlenmesi gereken endüstriyel ürünlerin güvenle taşınabilmesi için geliştirdiği palet örtüsü ürünü İlka Hood’un seri üretimine başladı. daha fazla